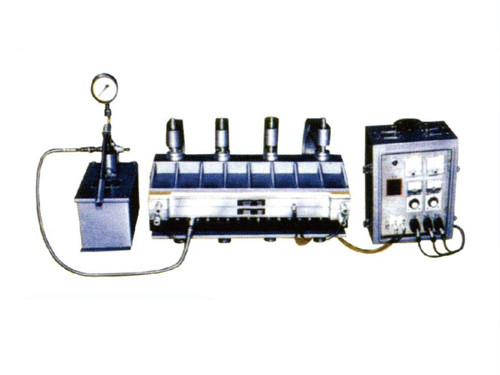

XBG-2 electric heating tape repairer

use:

During the operation of the belt conveyor, due to the deviation of the conveyor or the quality of the conveyor itself, the two sides of the tape are damaged, which affects the normal use. The repairing machine can not remove the roller in a short time (usually 3 hours) after the shutdown. In this case, effective vulcanization repair is applied to the edge damage.

Technical Parameters:

(1) Vulcanization temperature: 145 ° C

(2) Heating plate size: 700 × 350 (mm)

(3) Vulcanization pressure: 0.5Mpa

(4) Rated power: 3.6KW

XBG-2 type installation:

Tape repair, how to properly use the tape repair device to solve the belt damage (tape edge repair device, belt point repair device, belt line repair device)

(I) Purpose: If the cover and core of the tape are partially damaged, if the moisture and dirt are not repaired in time, the scar will be enlarged and the life of the tape will be shortened. In order to extend the life of the tape, find the defects in time and deal with it as soon as possible. The economic significance is undoubtedly huge.

(2) Repair of ordinary polyester tape

1. Working surface covering rubber damage

1) According to the damaged state of the cover rubber, it can be repaired in a circle or diamond shape, at least 15-20mm along the periphery of the broken contour, cut the repair line, cut it at an angle of 45º, and peel off the damaged cover rubber. Be careful not to damage the underlying fabric when cutting.

2) Prepare the repairing film, the size is consistent with the cutting surface, and the thickness is consistent with the original cover rubber (if the thickness is not enough, it can be laminated in multiple layers). film).

3) Trim the patch and patch, remove the impurities from the rubber particles, clean it, apply glue to the patch and patch, at least twice, and fully dry.

4) Laminate the repairing film and fully roll it firmly, and use the knife to lightly cut and smooth the excess plastic edge around the periphery.

5) Vulcanization repairer can be used for hot sticking. Refer to the tape gluing process.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!